This ultraviolet light- (UV-) hardened coating, which was developed using proprietary Mitsui Chemicals technology, resists fogging up and getting dirty.

NOSTRA™ | JEC2019

UV (ultra-violet) curable coating material

Applications detail

Acrylic UV coating material / Highly hydrophilic coating material

Applications

Characteristics

- Basic Information

- Details of Characteristics

- Details of Applications

NOSTRA™ is an ultraviolet light- (UV-) hardened coating developed using proprietary Mitsui Chemicals technology that resists fogging up and getting dirty.

The material has been given excellent dirt resistance, anti-fogging properties, easy washability, abrasion resistance, anti-static properties, and fast-drying properties.

Instantaneous drying (in several seconds) is a major feature, and the product is also attracting attention due to its resource-saving properties (low volatilization and low energy use) and amenability to production at volume as demand for such products rises in a broad range of fields.

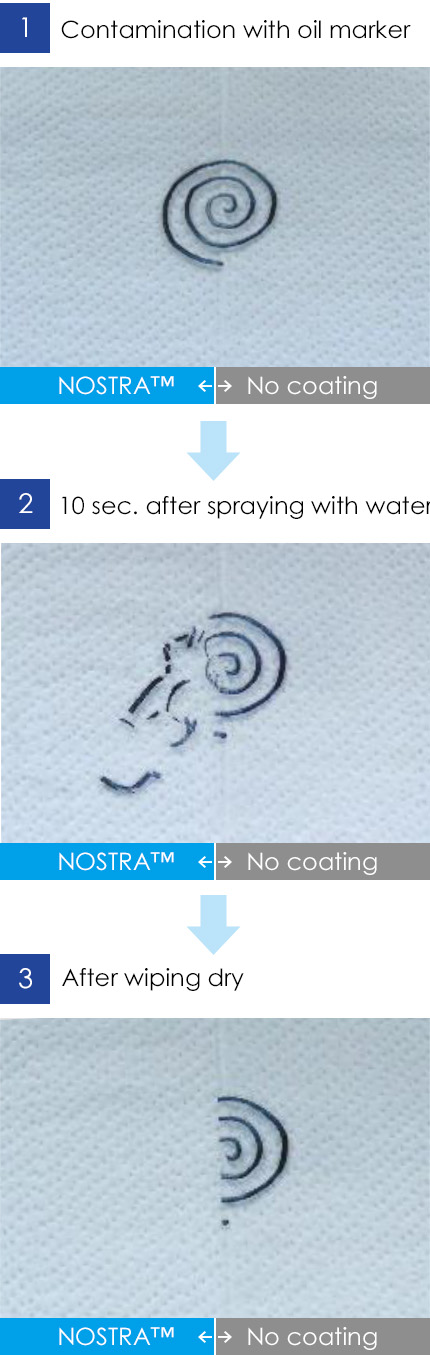

1. Easily washable; sheds dirt easily

NOSTRA™ makes it easy to remove dirt with water.

The material can be used to prevent accumulation of water scale

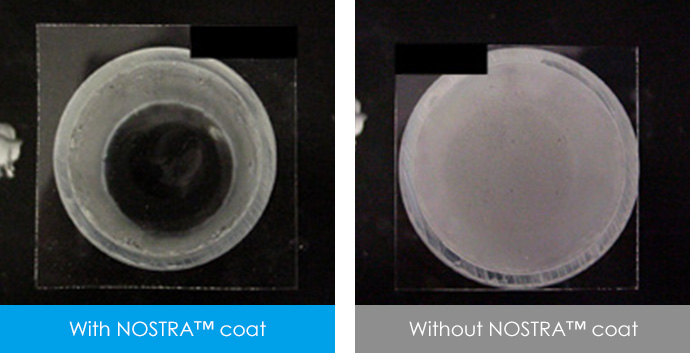

2. Resists fogging up

The material resists fogging up, making even glass surfaces in high-humidity environments resistant to condensation.

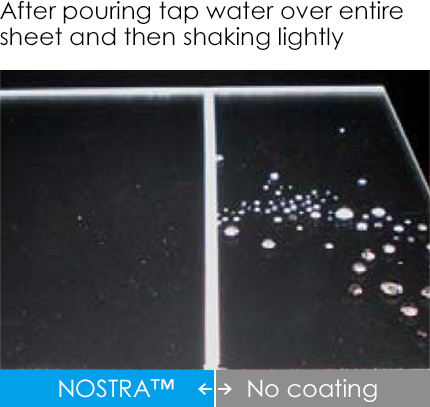

3. Dries quickly

Thanks to the material's super-hydrophilic properties and a water contact angle of 10° or less, water drains quickly away without forming into droplets so that the coating dries quickly.

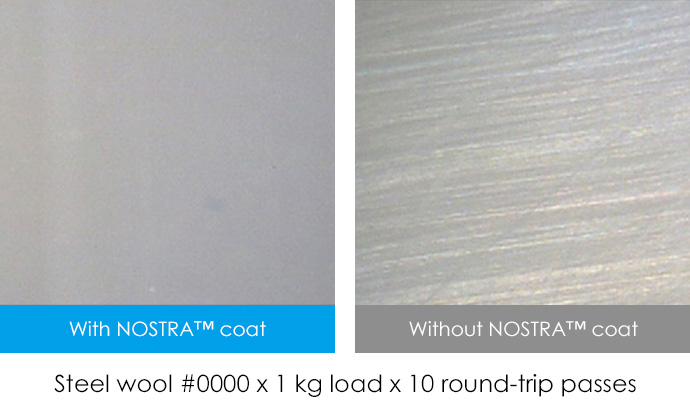

4. Resists scratching

The material resists scratching even when rubbed with steel wool, indicating its excellent abrasion resistance.

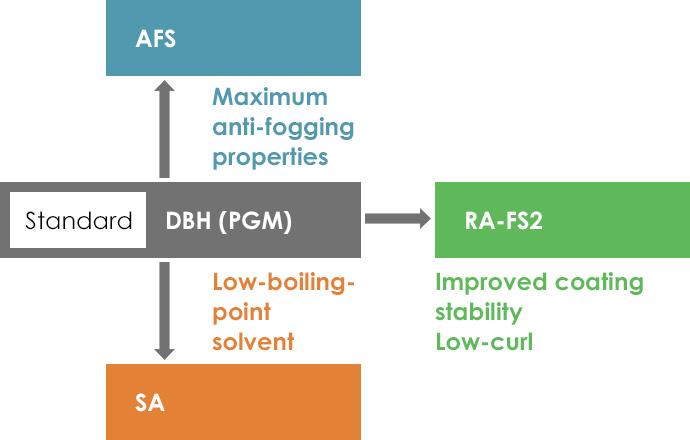

Representative grade

DBH (PGM): Standard

AFS (newly developed product): Designed for maximum anti-fogging properties

SA: Fast-drying

RA-FS2: Improved application stability; low-curl

Evaluation of liquid

| Grade | Appearance | Nonvolatile portion (wt%) | Type B viscosity: 25°C (mPa・s) | Solvent |

|---|---|---|---|---|

| DBH (PGM) | Transparency | 80 | 830 | PGM |

| SA | Transparency | 80 | 90 | Methanol |

| RA-FS series*1 | Transparency | 60 | 1200 | PGM and other |

| AFS*1 | Slightly turbid | 80 | 160 | PGM |

| *1: Newly developed product *Figures are representative values, not guaranteed. | ||||

Evaluation of coating film

| Grade | Appearance | Water contact angle θ (°) | Haze % | Abrasion susceptibility*2 | |

|---|---|---|---|---|---|

| 1 kg load | 3 kg load | ||||

| DBH (PGM) | Transparency | < 10 | < 1 | ○ | △ |

| SA | Transparency | < 10 | < 1 | ○ | △ |

| RA-FS series*1 | Transparency | < 10 | < 1 | ○ | ✕ |

| AFS*1 | Transparency | < 10 | < 1 | ✕ | ✕ |

| *1: Newly developed product *2: Steel wool #0000 x 10 round-trip passes ○: No scratching △: 5 or fewer scratches ✕: 6 or more scratches *Figures are representative values, not guaranteed. | |||||

Architectural films

The material yields easy washability and anti-fogging properties when applied to a surface such as a bathroom mirror.

- - Bathroom mirrors

- - Product display cases

- - Store windows

Automotive films

The material delivers anti-fogging properties and dirt resistance in high-humidity environments.

- - Car navigation system touch panels

Automotive parts

The material delivers anti-fogging properties and dirt resistance in high-humidity environments.

- - Windshield

- - Windows

- - Mirrors

- - Headlights

- - Tail lights

- - Instrument panels

- - Consoles

Aircraft parts

- - Cockpit glass