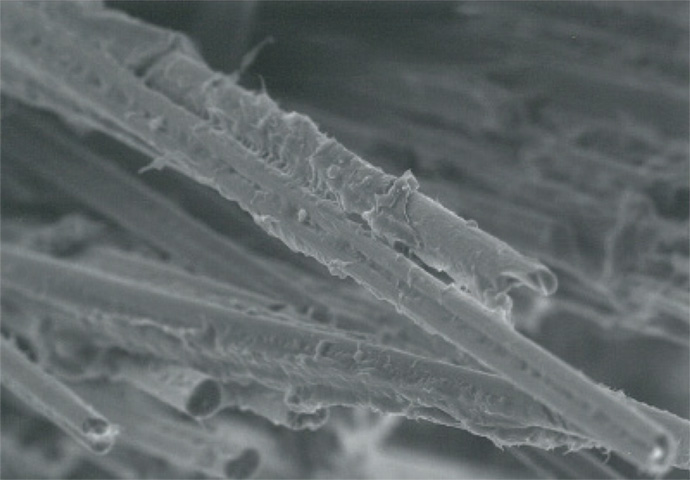

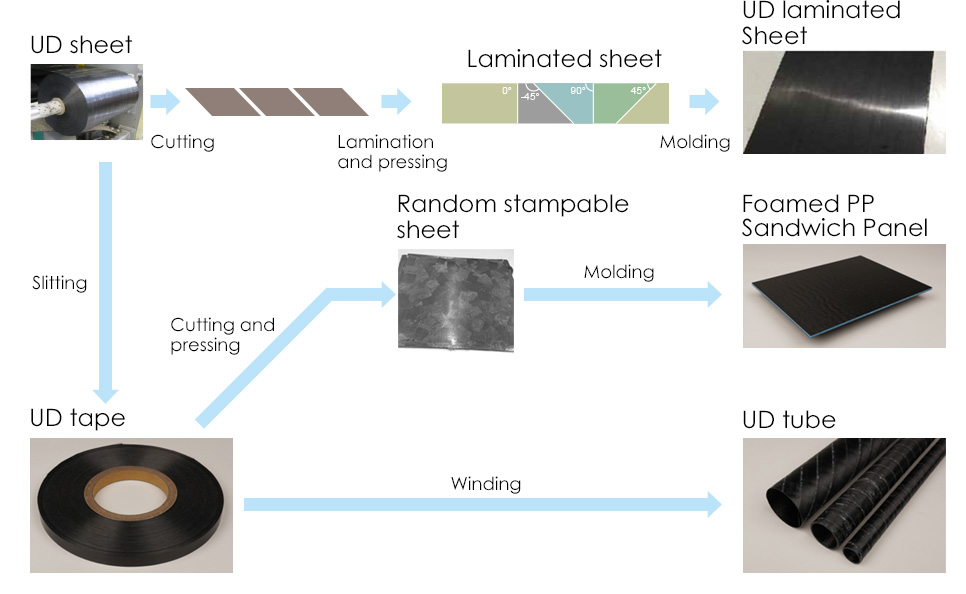

TAFNEX™ CF/PP is an unidirectional tape (UD tape) composed of carbon fiber and polypropylene (PP) achieved by unique technology of Mitsui Chemicals. It can be applied for local reinforcement of injected or pressed molded parts and also for parts in the form of tubes or laminated sheet.

TAFNEX™ CF/PP

Carbon fiber composite material *CF Solution partner : FORMOSA PLASTICS CORPORATION

Applications detail

UD Winding Tube / Foamed PP Sandwich Panel / Laminated Sheet

Applications

Characteristics

- Basic Information

- Details of Characteristics

- Details of Applications

TAFNEX™ CF/PP is an unidirectional tape (UD tape) composed of carbon fiber and polypropylene (PP) achieved by unique technology of Mitsui Chemicals.

Using this material for local reinforcement can reduce part weight while retaining strength.

Since it is a thermoplastic composite, it offers excellent processability; short processing time, secondary processing, and so forth.

In the automotive and bicycle field, TAFNEX™ CF/PP can contribute to reduce part weight, improve impact resistance and control vibration.

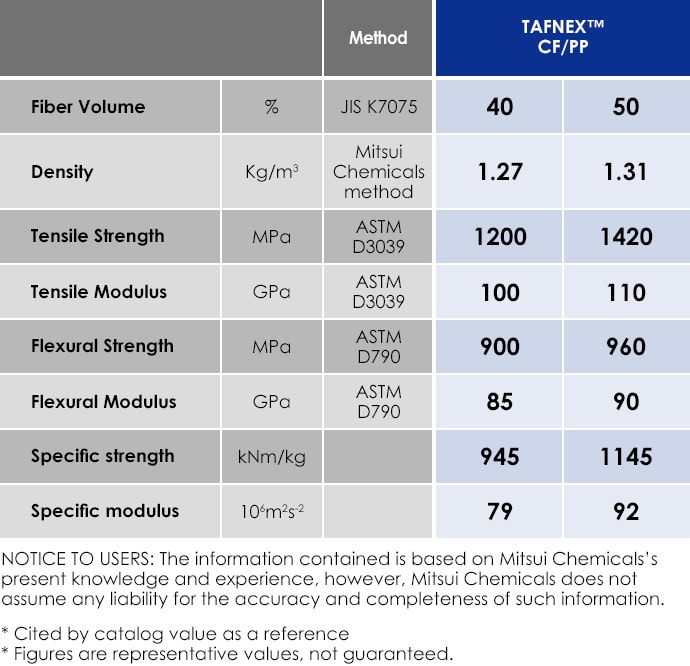

1. Light and strong

Combination of CF and PP realizes low density, high specific strength and high specific modulus.

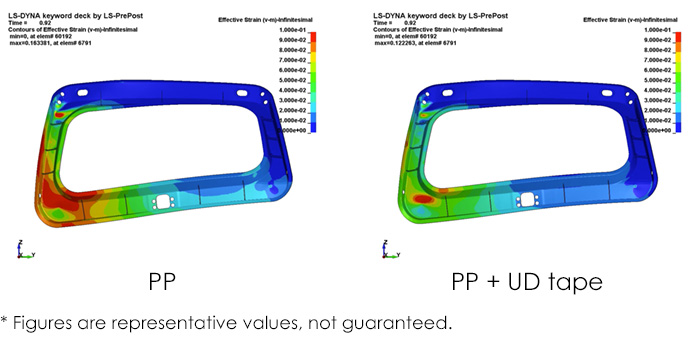

CAE analysis results

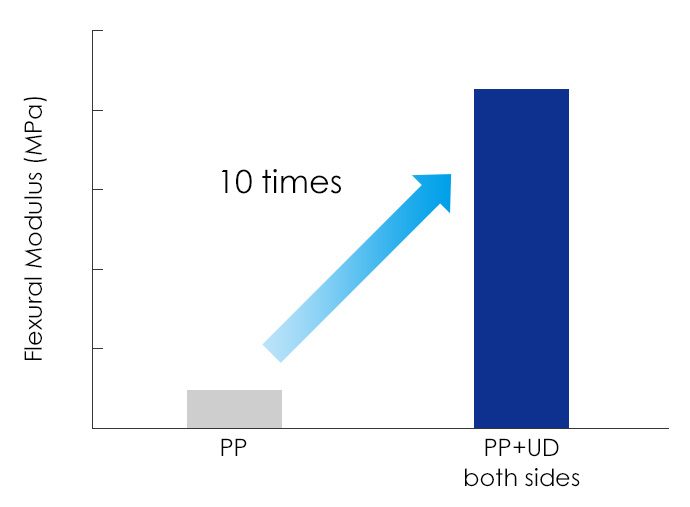

2. Reinforcement effect to increase mechanical properties of PP

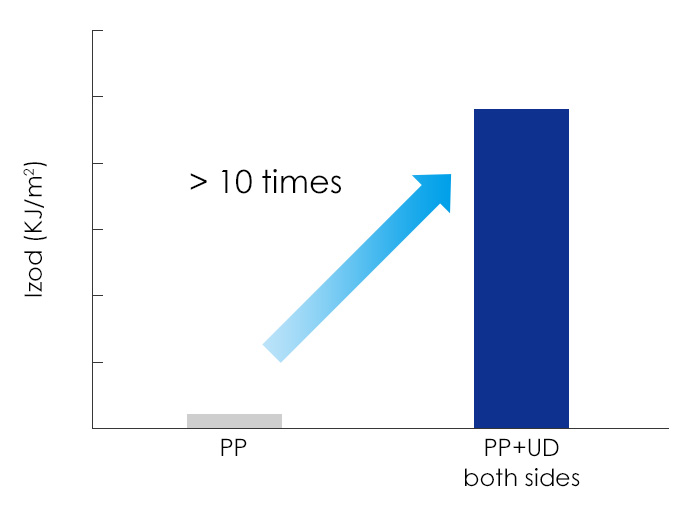

Significant increase of improvement in resistance to stress in standard specimens was observed by the reinforcement of CF/PP UD tape.

- Flexural modules: 10 times

- Impact resistance (Izod): more than 10 times

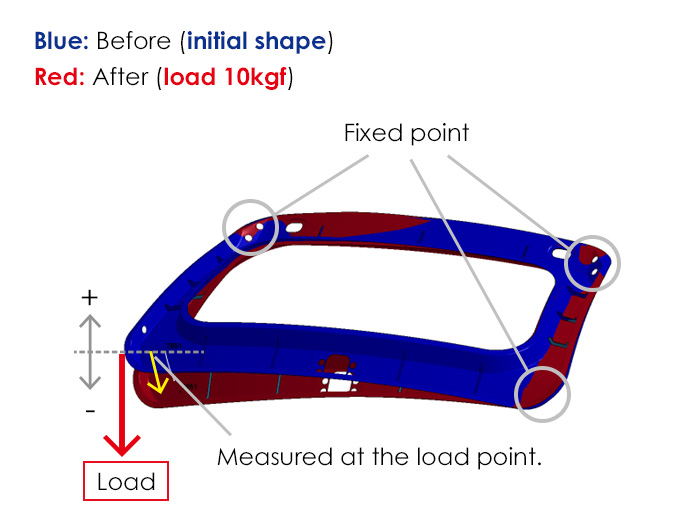

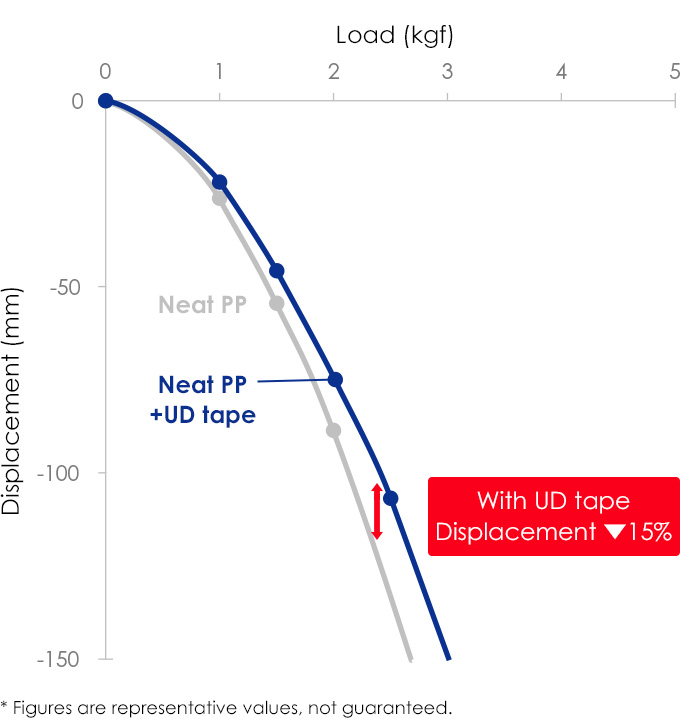

By locally reinforcing polypropylene with UD tape, the material’s resistance to deformation under load can be increased.

Example: Experimental results for UD tape reinforcement using a simple model of an automotive tailgate

Measurement method of displacement degree

Example: Simulation results of strain for a tailgate

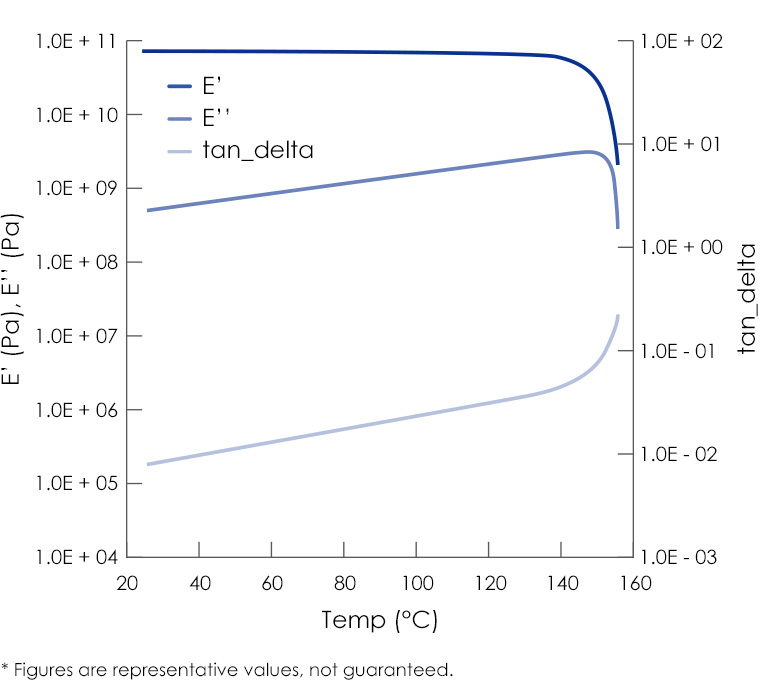

3. Resistant to distortion, even at high temperatures

The material retains a high flexural modulus at temperatures approaching its melting point of 140°C.

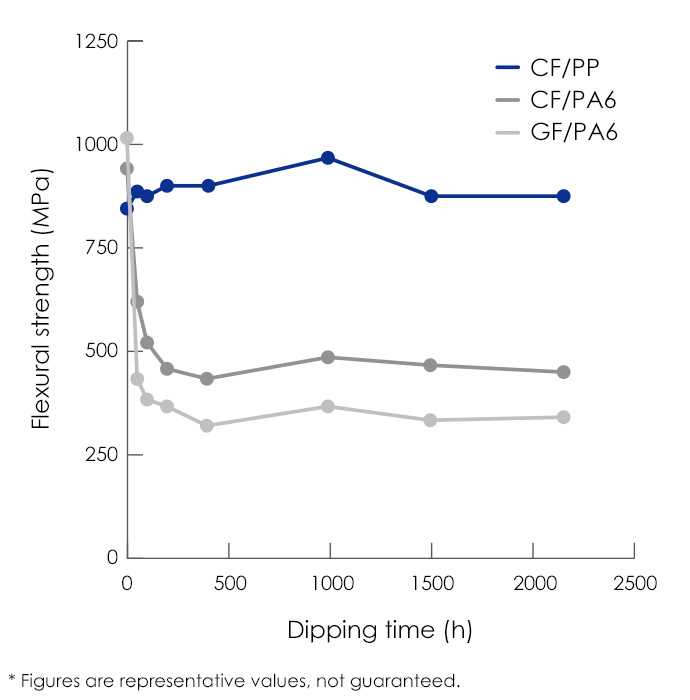

4. Remain mechanical properties in immersed and high-humidity environments

Since the material does not absorb water, bending strength can be maintained even when immerged in water for an extended period of time.

5. High processability

Since TAFNEX™ CF/PP is a thermoplastic composite, it offers excellent processability.

Shorter cycle time than thermoset composite is achieved due to the absence of heat-curing process.

In addition, molded parts can be reprocessed under heat or pressure.

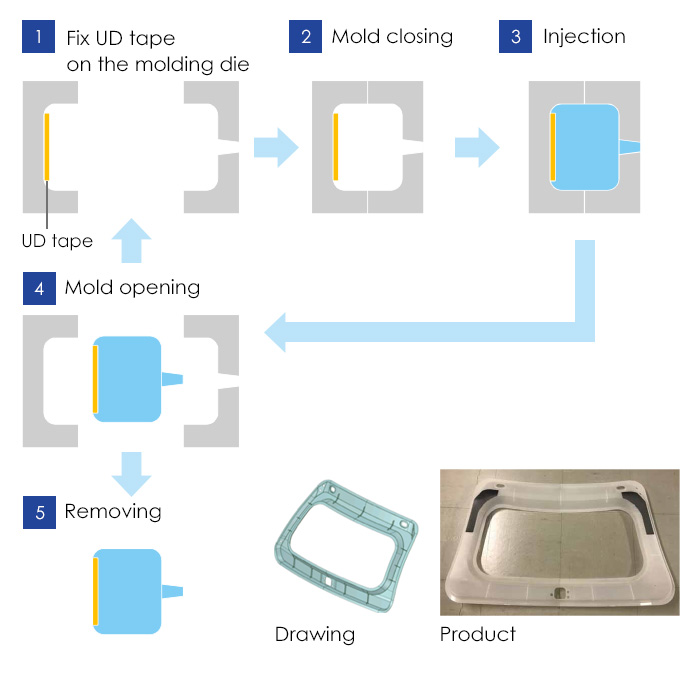

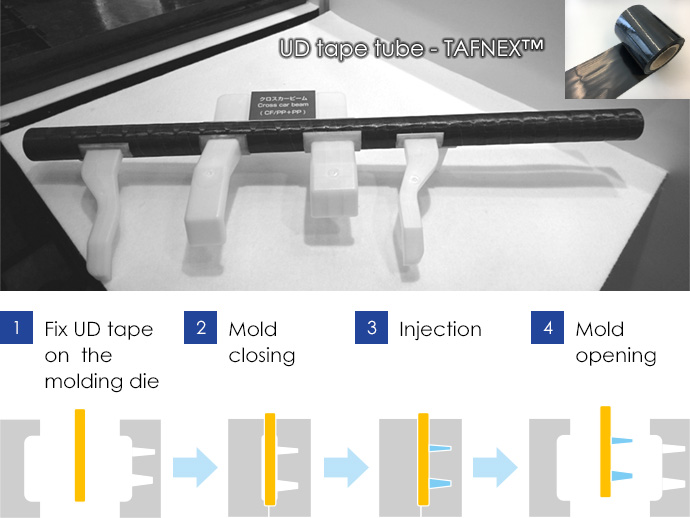

Example: Sheet insertion in injection mold

Example: Tape placement molding

6. Processable into parts

The material can be processed into parts in a variety of shapes, e.g. sheets, tubes.

Example: Cross-car beam; weight reduction and short processing time

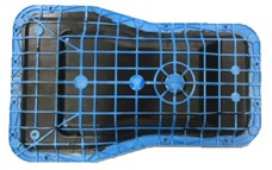

Example: automotive oil pan; molding of 3D shapes

Automotive parts

Weight can be reduced while retaining strength.

- - Tailgate

- - Bumper

- - Door

- - Instrument panel

- - Roof

- - Bonnet

- - Luggage board

- - Undercover

- - Oilpan

- - Floor panel

- - Other interior/ exterior parts

Consumer parts

- - Various consumer applications