Teach me the absolute basics I’m too embarrassed to ask

Lessons on Lenses for Opticians

Lesson 01Abbe Number: A number that determines the viewing comfort of glasses

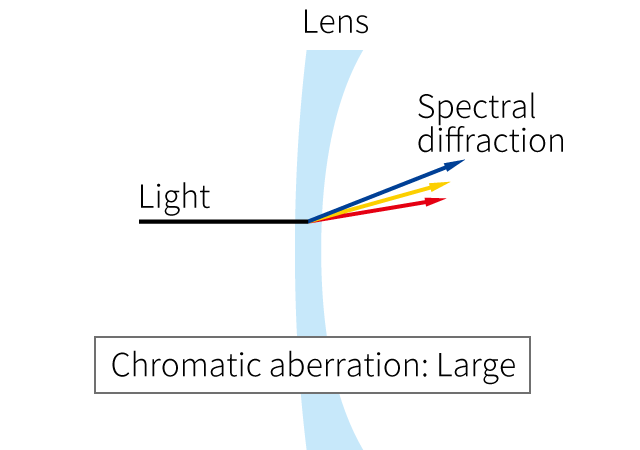

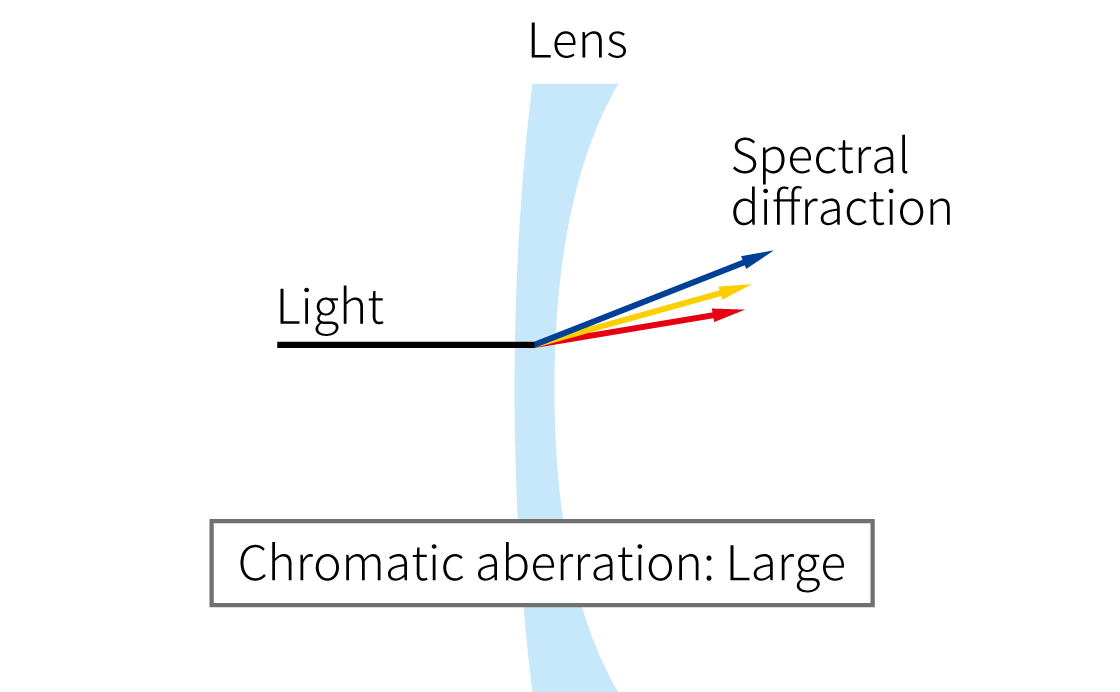

When light passes through a lens (prism), it’s dispersed into constituent spectral colors, due to the dependence of the refractive indexes on wavelength. We sometimes notice this phenomenon as color fringing (chromatic aberration) in blue or red in the field of view as seen through a lens. The aberration is especially noticeable in the peripheral regions of the lens, where the larger angle of incidence results in greater dispersion.

The Abbe number indicates the degree of light dispersion. Higher Abbe numbers mean lower dispersion, reduced chromatic aberration, and higher visual quality.

blurred image

In general, the Abbe number tends to be lower for plastic lens materials of higher refractive indexes. This means opticians face a dilemma: choosing lenses with a higher refractive index to reduce thickness will result in more apparent chromatic aberration.

But this dilemma can be avoided altogether by choosing both high R.I. and high Abbe number materials like MR-8™. This makes it possible to build thin lenses without the risk of chromatic aberration.

| MR-8™ | Polycarbonate | Acrylic | ADC* | Crown glass | |

|---|---|---|---|---|---|

| Refractive index (ne) | 1.60 | 1.59 | 1.60 | 1.50 | 1.52 |

| Abbe number (νe) | 41 | 28~30 | 32 | 58 | 59 |

| High R.I. and high Abbe number | High R.I. but low Abbe number | Low R.I. but high Abbe number | |||

| Refractive index (ne) | Abbe number (νe) | ||||

|---|---|---|---|---|---|

| MR-8™ | 1.60 | 41 | High R.I. and high Abbe number | ||

| Polycarbonate | 1.59 | 28~30 | High R.I. but low Abbe number | ||

| Acrylic | 1.60 | 32 | |||

| ADC* | 1.50 | 58 | Low R.I. but high Abbe number | ||

| Crown glass | 1.52 | 59 |

*ADC: Allyl diglycol carbonate

Lesson 02Choosing Your Lens Based on Strength

To keep your eyeglass lenses in perfect condition for as long as possible, you need to focus on lens strength. The word strength, as used here, refers to overall resistance against deformation and breakage and encompasses a wide range of distinct properties, such as stress resistant to cracking or abrasion resistance. This means you need a good understanding of the differences between the various lens material properties.

Selection Based on Stress Resistant to Cracking

To measure stress resistant to cracking, you need to understand the property called toughness in addition to the simple strength of an object.

Toughness refers to resistance against breaking when exposed to shock or pressure. We can also refer to the tenacity of a material. For example, while porcelain and glass both have a certain strength and resist deformation, neither is especially tough and both tend to crack or chip.

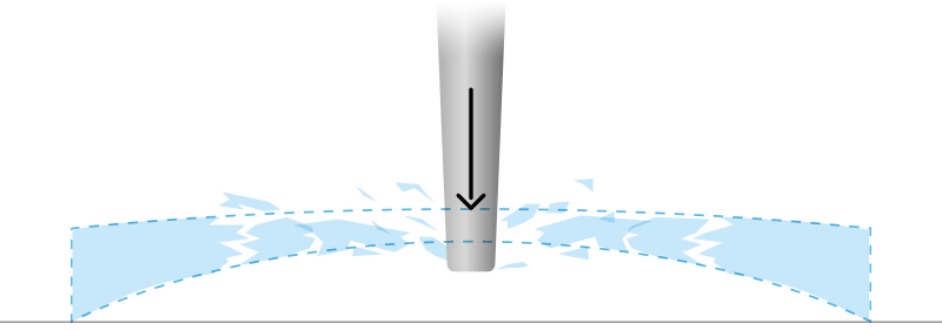

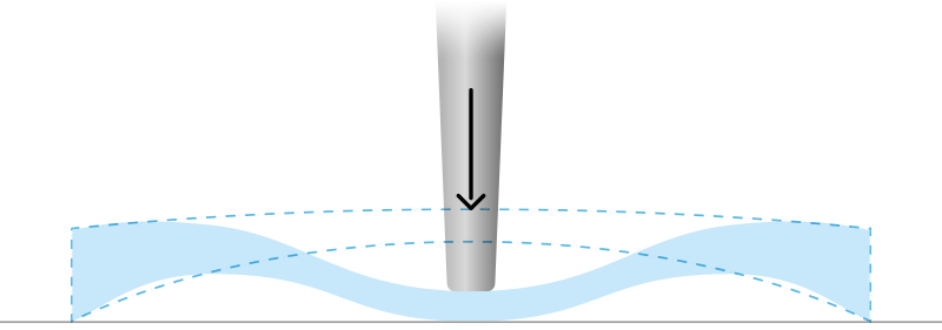

In the case of plastic lenses, toughness differs among various plastic materials. Medium R.I. lenses and acrylic lenses have relatively low toughness and are prone to breaking. In contrast, thiourethane MR™ materials not only offer high impact resistance, but high toughness as well. The material is more likely to deform without breaking when force is applied, rather than cracking or chipping.

Selecting Based on Abrasion or Scratch Resistance

Even if a lens resists cracking, it will not be ideal for long-term use if it is not scratch-resistant. The thiourethane material often achieves better adhesion results to the coating, allowing use under harsh conditions, including high temperatures. The coating will enhance resistance to cracking even when the lens is scraped against a surface.