Unique Properties

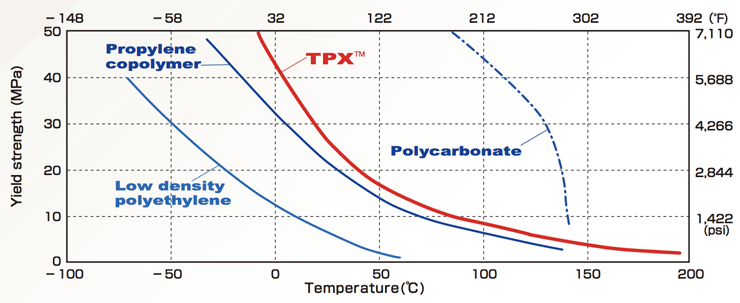

Heat Resistance

TPX™ has a high melting point in the range from 220°C to 240°C and a high vicat softening temperature. Hence, it can be used for high temperature application. However, as heat distortion temperature of TPX™ is almost same as that of polypropylene, the application under high-stress environment needs to be carefully considered.

Applications: Food Containers, Release Film for FPC, Rubber Houses, Release Paper foe Synthetic Leather, Animal Cage, LED Mold

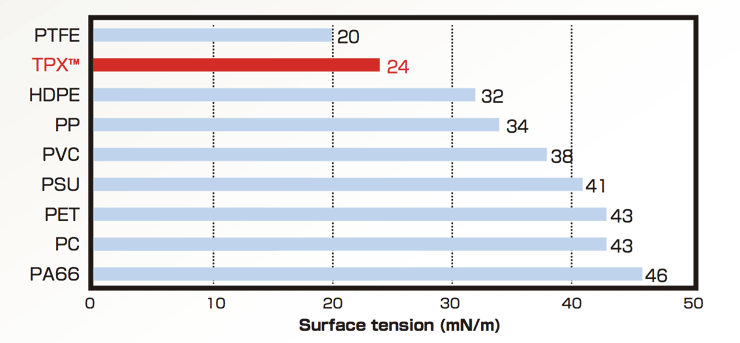

Releasability and Non-compatibility

The surface tension of TPX™ (24mN/m) is very low and this value is the secondary lowest as compared to fluorine polymers. Hereby, TPX™ shows excellent releasability against various materials in hardening process of thermosetting resins (urethane, epoxy etc.) Furthermore, since TPX™ shows incompatibility against thermoplastic resins (PET, PP etc.) it is used to create a porous structure in PET or membranes.

Applications: Food Containers, Release Film for FPC, Rubber Houses, Release Paper foe Synthetic Leather, Resin Modification, LED Mold

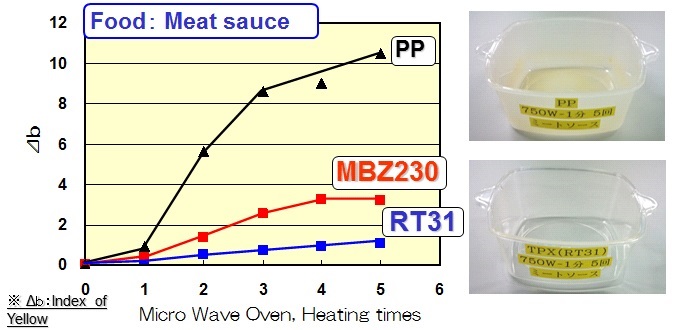

Releasability and Non-compatibility

With the superiority of releaseability, TPX™ can hardly to be stained with food. The antifouling property is also a strong point of TPX™.

The chart above shows the contrast among normal PP and TPX™ on food stain antifouling property. It is clear that compared to other materials, the containers made from TPX™ is hardly stained.

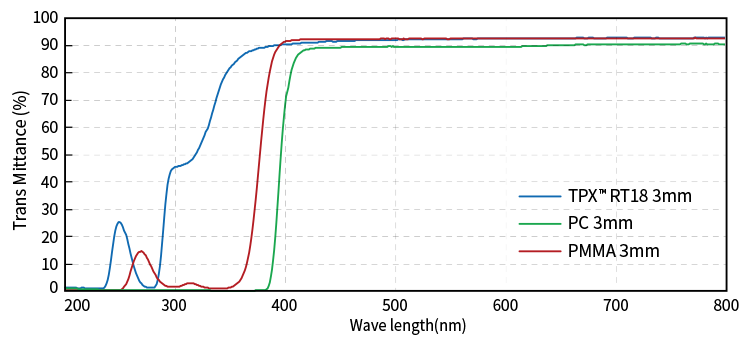

Transparency

Although TPX™ is a crystalline polymer, it exhibits excellent transparency (Haze:<5%) and light transmittance. Especially TPX™ is used for optical analysis cells because of the higher UV transmittance as compared to glass and other transparent polymers.

Applications: Food Containers, Animal Cage, Experimental Apparatuses

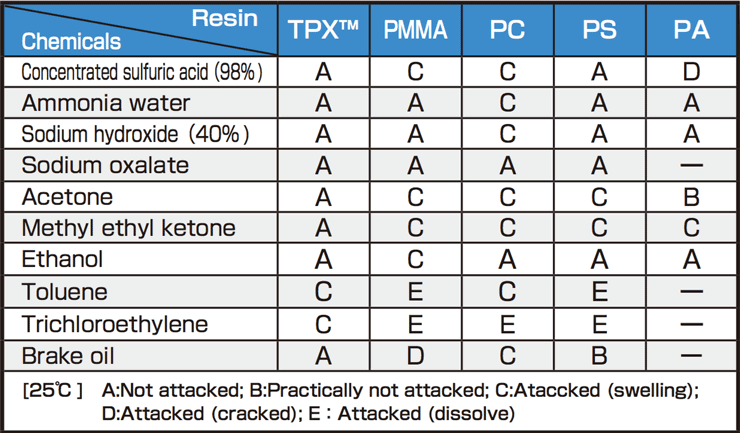

Chemical Resistance

Because of its stable C-C bonds, TPX™ has better chemical resistance as compared to polycarbonate and acrylic polymer. TPX™ basically shows excellent chemical resistance particularly against acids, alkalis and alcohol. For this reason, TPX™ is used in various applications which require chemical resistance, such as cosmetic container caps and tubes, experimental apparatus and analytical cells.

Applications: Experimental Apparatuses

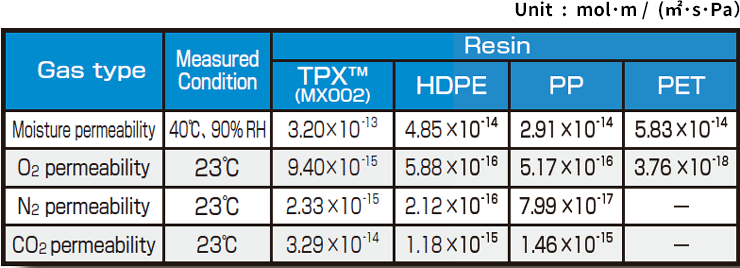

Gas Permeability

TPX™ has a characteristic of excellent gas permeability derived from its molecular structure. Hence, TPX™ is widely used for gas permeative applications such as gas separation membranes.

Applications: Hollow Fiber

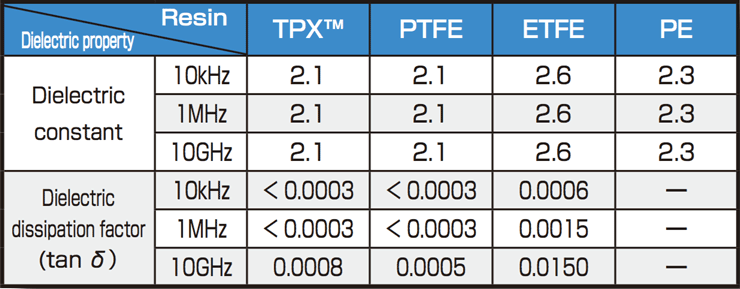

Low Dielectric Property

Since TPX™ has a non-polar structure; its dielectric property is almost same as fluorine polymers. It should be noted that dielectric property of TPX™ is hardly affected by frequency and TPX™ can be injection-molded unlike PTFE. TPX™ shows stable dielectric property in the wide range of frequency.

Low Dielectric Property

Low Density

The density of TPX™ is the lowest (830 kg/m3) among thermoplastic polymers, and its specific volume is larger than that of other transparent polymers. For this reason, it is possible to reduce the weight of injection-molded articles by using TPX™ or also TPX™ compounds.

Applications: Food Containers, Animal Cage

Steam Resistance

TPX™ shows a very low water absorbance and therefore the dimension of a TPX product is hardly affected by water absorbance. Furthermore, since TPX™ does not hydrolyze in boiling water, it can be used for experimental apparatus and animal cages which require the steam sterilization.

Applications: Hollow Fiber, Experimental Apparatuses, Animal Cage

Food Sanitation

Hygienic approved TPX™ grades (JPN standards, FDA and EU regulations) are also available. And with its excellent heat resistance property, TPX™ is often used for food wraps and microwave oven table ware.

Low Refractive Index

The refractive index of TPX™ is 1.463nD20, lower than fluorine polymers.

Application

Supplement Information for Physical Properties

- PDFPropertiesdocument1

- PDFPropertiesdocument1

- PDFPropertiesdocument1

- PDFPropertiesdocument1

- PDFPropertiesdocument1

- PDFPropertiesdocument1

- PDFPropertiesdocument1

- PDFPropertiesdocument1

- PDFPropertiesdocument1

![TPX [TM]](/en/special/tpx/img/logo.png)