Mitsui Chemicals conducts various initiatives to strengthen safety and quality in logistics. In recent years, in particular, the chronic shortage of logistics personnel on a global scale, combined with the 2024 issues*1 in Japan, has made the lack of experience and insufficient transfer of skills an extremely important issue in maintaining the safety and quality that are the foundation of logistics. Therefore, the Company focuses on joint education with its logistics partners to improve logistics safety and quality.

Specifically, the logistics RC promoters appointed from the divisions in charge of logistics at the Head Office and each Works conduct mutual plant patrols as well as training to improve technical capabilities. In the procedure of cross-checking by leaders from other Works, from a third-party perspective, they check the work environment and the status of maintenance and management of equipment and facilities. By sharing not only the points to be improved or concerns, but also good practices, we aim to standardize and raise logistics safety and quality.

Furthermore, we believe that in order to achieve logistics that ensures safety, environment, and quality, it is important for the logistics field to be fully aware of logistics RC, and we conduct logistics RC education and training jointly with our logistics partners. In addition, we instruct and confirm that our logistics partners conduct the same management when they re-consign the operations to their partners. Third-party logistics (3PL)*2 companies take the lead in managing 3PL products. The aforementioned activities are also undertaken with the logistics division at each of our Works playing a supporting role.

Logistics

Safety and Quality in Logistics

Education on safety and quality for logistics work

Initiatives that include logistics partners

- Sharing of logistics trouble and near-miss cases at logistics council meetings, worksite patrols at own Works, and education on trouble prevention using a collection of trouble cases

- Group education and training on the handling of hazardous materials

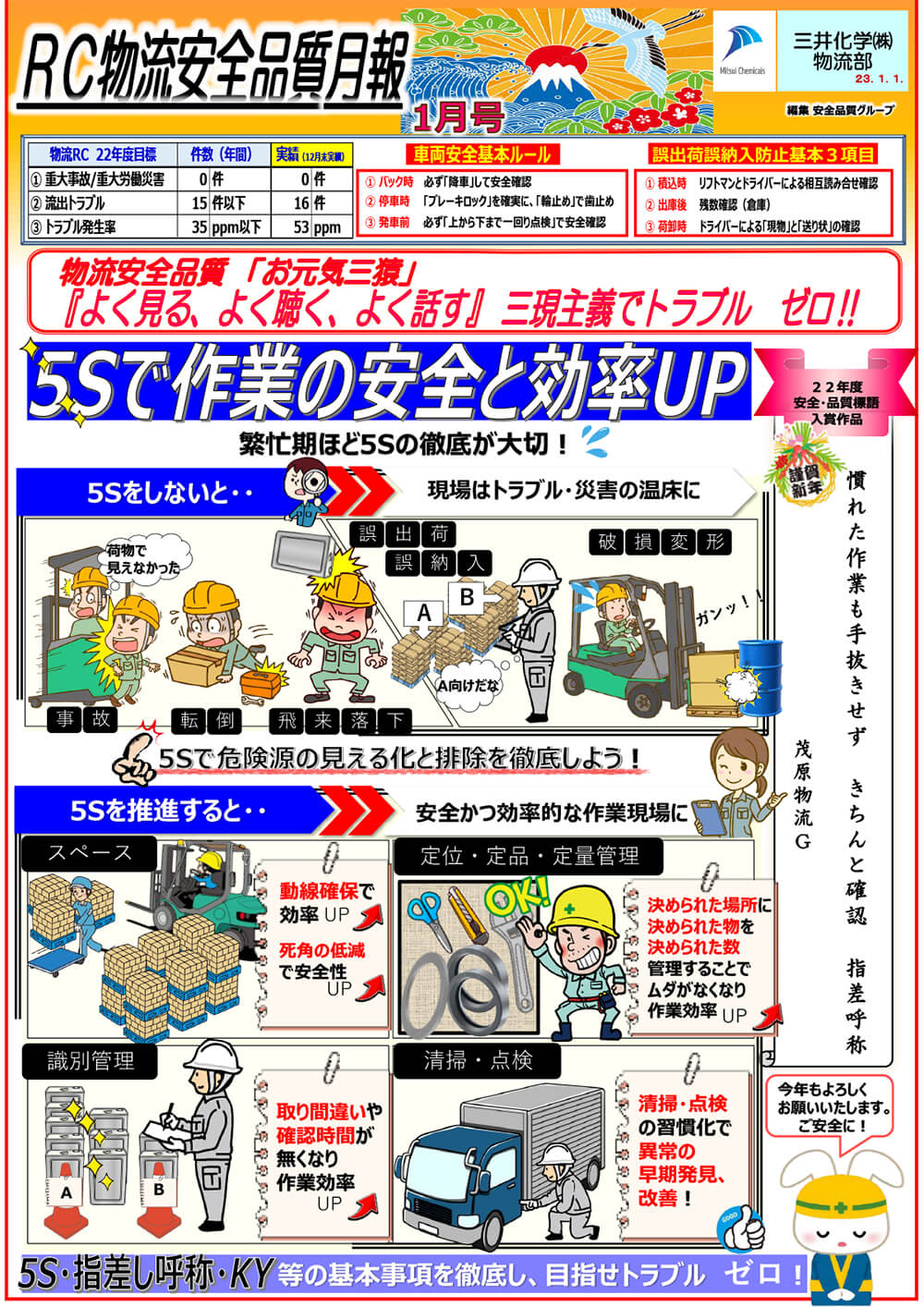

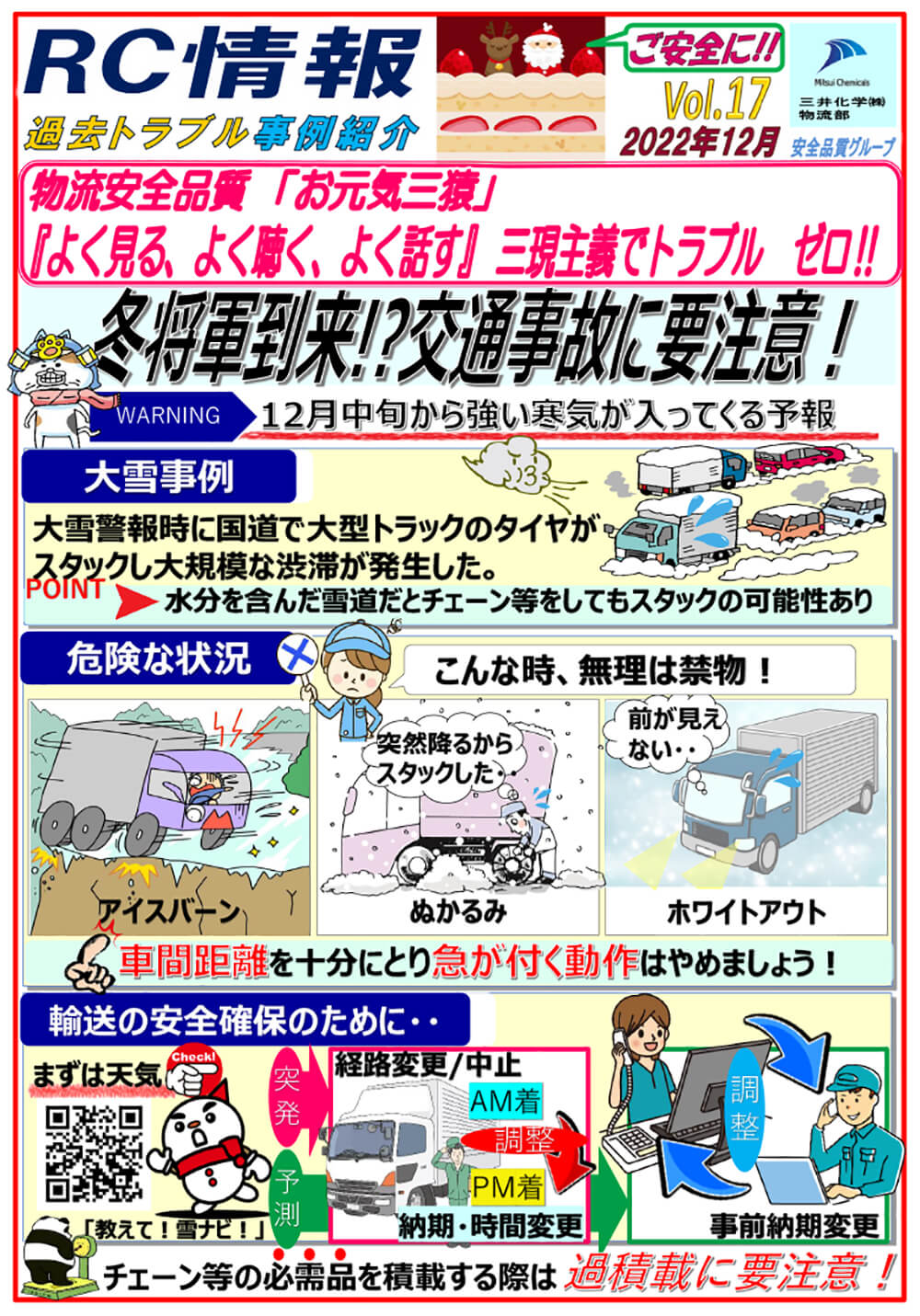

- Raise awareness of logistics safety and quality through the monthly reports on safety and quality for logistics RC and RC News, which provide easy-to-understand information on examples of logistics-related problems, the importance of protective equipment, and seasonal considerations (heat stroke prevention, etc.).

- Safety talks (interviews) with worksite personnel

*1 2024 issues:

From April 1, 2024, the grace period for applying the truck driver overtime regulations will end and the limit of 960 hours of overtime per year will apply to truck drivers, so there are concerns about a further shortage of drivers in Japan.

*2 Third-party Logistics (3PL):

A form of logistics operation where other companies undertakes all or a portion of logistical tasks.

Drills with affiliates (disaster drills)

Drills with affiliates (disaster drills)

Trainings with affiliates (vehicle width sensory demonstration)

Trainings with affiliates (vehicle width sensory demonstration)

“Monthly reports on safety and quality for logistics RC”

Call for safety measures, including the use of appropriate protective gear

“RC News”

Closer communication with logistics partners on Responsible Care

Cross-checking patrol

Safety Measures for Product Transportation

Provision product information

The Mitsui Chemicals Group products include hazardous substances specified by the United Nations Recommendations on the Transport of Dangerous Goods*1 and Japan’s Fire Service Act and other domestic laws. In order to ensure the safe handling and transportation of products, the Group provides information on safe handling and storage precautions through Safety Data Sheets (SDS) to its subcontractors, regardless of whether or not the products are hazardous or toxic. We also submit a Yellow Card,*2 which specifies the emergency response procedure and contact details in case of an accident, and mandate the logistics partners to carry the card during transportation.

We have also developed a system to manage the distribution status of provided SDSs and Yellow Cards in a ledger and to swiftly provide the latest information when it is renewed.

*1 United Nations Recommendations on the Transport of Dangerous Goods:

A recommendation developed by the United Nations Economic and Social Council's Committee of Experts on the Transport of Dangerous Goods in order to ensure the safety of international transportation of such goods, updated every two years. Depending on the danger and hazard level, dangerous goods are classified as follows: 1 explosives; 2 gases; 3 flammable liquids; 4 flammable solids; 5 oxidizing agents and organic peroxides; 6 toxic and infectious substances; 7 radioactive substances; 8 corrosive substances; and 9 miscellaneous.

*2 Yellow card:

An emergency contact card on which are written the actions to be taken by those involved, including the truck driver, fire and police, in preparation for the unlikely event of an accident when transporting chemical substances or high-pressure gas. Promoted by the Japan Chemical Industry Association.

Yellow card

Yellow card

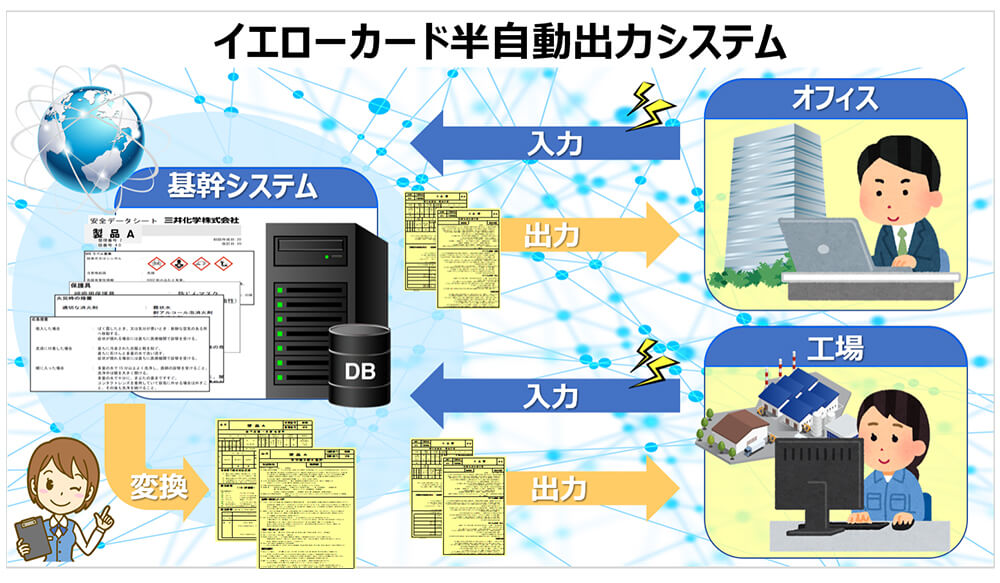

Image of the Yellow Card semi-automatic output system

Image of the Yellow Card semi-automatic output system

Collaboration with other companies in the same industry

The Mitsui Chemicals Group is keen to maintain safe and secure goods logistics by preparing for emergency situations, in addition to thorough compliance with relevant laws. As for High risk goods*, we are working together with other companies in the same industry to reinforce safety measures, such as organizing a mutual emergency support system, including stocking emergency response equipment and materials. In fiscal 2022, information exchanges on problems with transporting hazardous goods and other issues took place remotely. We are also considering DX initiatives to strengthen safety measures in the transportation of high-risk products.

*High risk goods:

Products that may have a significant social impact if a transportation accident occurs, determined according to its danger level, hazard level, transportation volume, etc.

Emergency response

As a shipper, the Mitsui Chemicals Group is taking steps to respond promptly and flexibly in the event of an accident during product transportation.

Preparing for logistics accidents in Japan

- Security and disaster drills by each plant to prepare for emergencies and disasters

As part of our emergency response training, we regularly conduct drills that simulate accidents involving the leakage of hazardous materials during transportation, as well as drills conducted in cooperation with our logistics partners. - Establishment of the Mitsui Chemicals Group Offsite Logistics Accident and Emergency Contact Network and Support System (MENET)

The network and support system (MENET) is divided into six areas covering different parts of Japan, and the major Works in each area is appointed as the emergency support provider that can be mobilized 24 hours a day. These designated Works continue to improve their emergency response capabilities through annual emergency contact and mobilization drills. - Contract signing for HAZMATers : Hazardous material accident response services with the Maritime Disaster Prevention Center

In addition to MENET, we are further strengthening our accident response system by utilizing specialized teams and specialized equipment and materials at the Maritime Disaster Prevention Center. - Maintenance of equipment in case of vehicle accidents

In preparation for cases where product transportation is disrupted due to a vehicle accident or for other reasons, we have been developing equipment to safely extract products from such a vehicle, etc. In fiscal 2021, we deployed a portable abatement system that is needed to extract high-pressure liquefied gas at Osaka Works. When deploying this system, we provide instructions on how to use it and group training on safety, including to our logistics partners.

Preparing for global logistics accidents

- Introduction of Chemicals 24-hour Emergency Response Service (Carechem24)

By utilizing the emergency telephone response service provided globally by the National Chemical Emergency Centre (NCEC), we are able to respond promptly and accurately to overseas distribution accidents and inquiries about our Group’s products, and we are also promoting the strengthening of the global logistics RC management system.

MENET Support Providers and HAZMATers Emergency Response Bases

Demonstration using the portable abatement system for liquefied high-pressure gas at the Osaka Works

Demonstration using the portable abatement system for liquefied high-pressure gas at the Osaka Works

Initiatives by Logistics DX

Improvement of logistics quality using digital technology

For greater efficiency in inventory control and shipment management, we have introduced the use of portable terminals. Inventory and shipping management is performed by reading QR codes attached to packages when receiving and shipping using a handy terminal; reducing the amount of work compared to conventional manual entry or input into spreadsheet software; and achieving a paperless operation. In addition, the introduction of the handy terminal has been effective in preventing erroneous shipments, whereas the previous method of visually checking brand names and lot numbers posed the risk of erroneous shipments due to misreading. Full-scale operation began at the Nagoya Works in fiscal 2019, with installation completed at the Ichihara Works in fiscal 2022.

In fiscal 2021, we also developed and installed a function that automatically outputs the information needed for a Yellow Card from our proprietary SDS system (Yellow Card semi-automatic output system). Actual operation began in fiscal 2022. The addition of this functionality has standardized and greatly reduced the workload of yellow card creation. This allows for speedier and more accurate communication of safety-related information throughout the logistics supply chain, leading to enhanced safety management.

Handy Terminal

Handy Terminal

Initiatives for supply chain optimization (SCM optimization PJ)

We are working to optimize the supply chain by promoting the visualization of actual logistics conditions using business intelligence (BI) tools. In order to solve the problems of data sharing, frequency of data collection, data granularity, and infrastructure for analyzing logistics data, we have established a common data infrastructure within the Company, and are developing an environment that enables regular analysis in the business and logistics divisions to visualize logistics costs and identify logistics issues. In the future, due to the logistics 2024 issues, it will be more difficult to transport goods over longer distances than before, so it is necessary to improve transportation efficiency by reviewing public warehouses and other measures. To improve the working environment for drivers, we will promote the reorganization of our logistics network.