The secret of Easy-Peel’s secure sealing and smooth unsealing

Walk the aisles of any supermarket and you can find tempting desserts such as jellies, puddings and yoghurts available in see-through containers. Many other foods, including tofu, fruit juice and precooked items, are also available in plastic containers. Just peel off the cover and the contents are ready to eat or drink. No effort or thought required.

Yet to make the sealing secure and simple to open took a great deal of thought and work. In fact, our scientists at Mitsui Chemicals Tohcello spent decades researching and developing the materials and technologies to achieve these results.

The magic behind smooth unsealing

Fig. 1 shows the steps taken to remove the cover of a jelly container. The lid peels off smoothly with the minimum of effort that even a child can open it. But, some containers are difficult to open, which can frustrate consumers. You may be surprised to learn why this occurs.

Fig. 1

Fig. 1

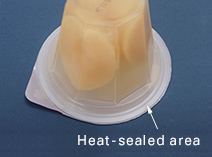

Note first, though, that the most important priority of a plastic food container is to prevent content contamination and leakage. This requires that the cover firmly seal in the contents, which is achieved using heat-sealing technology (Fig. 2).

Because the cover and container are made of different materials in many cases, the bonding strength between them depends on their compositional compatibility. If, for instance, the same material for both the container and cover are used, the surfaces can bond tightly together during heating, making removal of the cover frustratingly difficult.

Fig. 2

Fig. 2

Mitsui Chemicals Tohcello’s Easy-Peel film interfaces between the cover and container in order to provide them with the necessary compatibility. This ensures they achieve the dual goals of secure containment of the contents and smooth unsealing. The covers lined with our film remain firmly fixed to their containers during transportation from factory to convenience store and during their time on the shelves, yet they peel off easily when you are ready to remove them.

Thinner than a human hair!

When you open a gelatin dessert container, for example, the cover is rarely given a second thought. That’s hardly surprising, for it is “just” a cover measuring 100 microns thick, the average diameter of a human hair.

Yet, though the cover appears to be a single sheet, it is actually composed of three bonded films. The outermost layer is a base film on which the product’s name is printed. The second layer is a barrier film designed to protect the contents from oxygen and moisture. While the Easy-Peel adhesive film forms the innermost layer and measures a mere 50 microns in thickness.

Our Easy-Peel film business dates back to the 1970s, when Du Pont-Mitsui Polychemicals, one of our group companies, created a plastic material never produced before. After much trial and error, Mitsui Chemicals Tohcello successfully developed this soft and sticky material into a film. When it was introduced in 1980, however, sales were initially sluggish because of limited application.

The 1970s saw the debut in Japan of instant noodles offered in plastic containers. This sparked demand for easily removable container covers. Our film proved to have the required properties needed to satisfy this demand.

As plastic containers for such food items as jellies and tofu, later followed by precooked foods like rice and sliced ham became popular with consumers, demand for the film grew markedly. Today, the film is one of our leading product categories, and we provide a competitive lineup of film types, including one that is heat resistant.

Mitsui Chemicals Tohcello has spent years researching and developing technologies to create new types of film. For example, one technology blends together various materials, while another technology co-extrudes several materials to form multilayer films. Based on such experience, we have created a variety of Easy-Peel films. This has enabled different foods to be securely packed in plastic containers and their covers to be peeled off smoothly.

As society changes, technology must also evolve. Development of food products and packaging, for instance, seems to know no limit. The same is true for our Easy-Peel film. With the rapid aging of society, covers for food containers now need to be made even easier to remove. Continuously modifying our film is no simple matter, but it is a challenge we take up with pride, as part of our corporate mission to make customers’ lives more comfortable.

How Easy-Peel film works

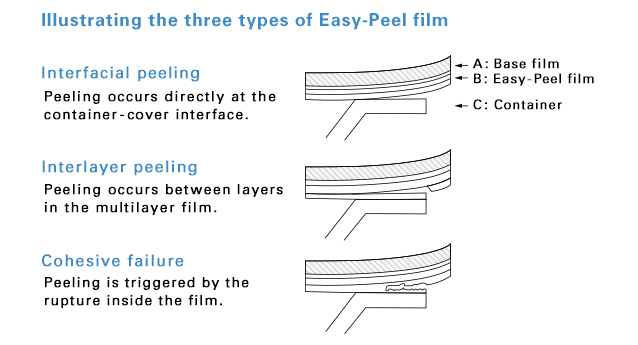

Why does the cover of a jelly container or other plastic food container peel off easily with such little effort? Following are explanations of how three different kinds of Easy-Peel film work.

The most basic type of Easy-Peel film simply unseals at the interface of the container and film (interfacial peeling) when force greater than the film’s adhesive strength is applied.

The second example uses interlayer peeling technology. This action, technically known as de-lamination, employs a multilayer film structure. It requires the adhesive strength between two specific layers of the structure to be less than the bonding strength of the heat-sealed cover on the container. This enables peeling to occur between these layers.

The third example uses a technology known as “cohesive failure” that employs a type of film heavily impregnated with tiny particles of a different material. When force is applied to remove the cover, rupture occurs between each particle and the surrounding film, which causes the film to split apart. Examine the container after Easy-Peel film employing cohesive rupture has been removed, and you will see white traces of the Easy-Peel film remaining on the container. (Fig. 3)

In the examples of interlayer peeling and cohesive failure, unsealing occurs inside the film, rather than between the actual cover and container. This is why removing a cover, even one that has been heat-sealed to the container, is simple and smooth. As a consequence, these covers produce a perfect seal yet are still easy to remove, and so have been widely adopted by the food processing industry.

Fig. 3

Fig. 3