The lens, which produces the images, is the part that determines a photograph's image quality. Camera lenses are compounds of convex and concave lenses. Ordinary cameras have used large-diameter glass lenses, but smartphone camera lenses have to be small and light.

"APEL™" resin for use in ultra-compact smartphone camera lenses

"Looking at beautiful scenery? Enjoying a delicious meal? Take a photo and post it on social media!" That's something that couldn't even be imagined until the camera-equipped smartphone made its appearance. But though smartphone cameras are much smaller than conventional cameras, they produce high-quality pictures. Making that possible is an ultra compact compound lens made of resin, and of the resins on the market, APEL™, Mitsui Chemical's high-performance convex-lens resin, boasts more than half the world's market share.

It's the camera lens that determines the clarity of a photograph

The advent of smartphones equipped with cameras has made taking pictures handier than ever. It's easy to upload the photos on the net, too, so we share information almost instantly now. This has meant a major change in lifestyle.

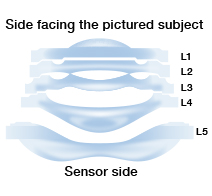

The camera mounted on a smartphone is small, but it contains the lens that gathers light and creates an image, along with "sensors" that record the image, etc. In that sense, it doesn't differ much from a conventional camera in its basic structure.

The structure of a smartphone camera

Making small lenses out of glass requires time and effort for cutting and polishing, so productivity is poor and costs go up. That led manufacturers to begin to choose camera-appropriate plastics that are easily molded for use.

The evolution of the smartphone accelerated the demand for a high-performance lens that produces high-quality images. The key proved to be Mitsui Chemical's APEL™, a plastic with excellent optical properties. At its smallest, the convex lens is 4 mm in diameter and 0.2 mm thick.

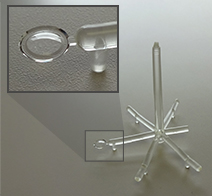

The process by which APEL™ pellets become smartphone camera lenses

Pellets are heated and melted, poured into metallic molds and molded.

The thin disc-shaped object at the tip of the molded product is the lens. It is cut off, combined with other lenses to form lens unit, and mounted on the smartphone camera.

Of the five lenses (L1-L5) in the lens unit, the three convex lenses (L1, L4, and L5) are made using APEL™.

Why APEL™ is the preferred material for smartphone lenses

The role of a camera lens is to capture light, refract it, focus it, and create the image that will become the photograph. This means that making a small camera requires a transparent, high-refractive index lens that can capture sufficient light even through a small aperture and that can focus up-close even though it's thin. APEL™ makes such lenses possible.

Additionally, lenses made with APEL™ have small birefringence. Birefringence in lens materials causes an optical distortion that makes a ray of light divide into multiple rays, which causes blurring in the image passing through the lens. A small birefringence allows for clear photographs without blurring.

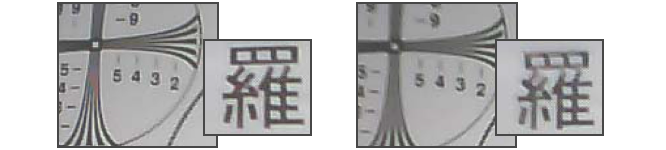

Difference in picture quality due to differences in lens material

Two lens units are made, one using two APEL™-made convex lenses and one using two convex lenses of comparable materials (with the same concave lenses in both). Patterns and letters are drawn on each. It is obvious that a photo with the APEL™ (left) lens unit is clearer. This is thought to be because the impact of birefringence is especially evident with thin lenses.

APEL™'s superior properties come from the molecular structure of the material. For details, see "Molecular structure: the secret to a non-blurry image."

APEL™ is also characterized by low water absorptivity. This means the lens is stable in relation to temperature and humidity, and therefore that environmental changes will not exert much impact on picture quality.

APEL™ was originally developed as a base material for optical discs in the early 1980's. Its development was suspended, however, because of pressure from low-priced competitors. Production continued on a very small scale, but the APEL™ business remained on the brink of folding.

The reason it was able to break out of this position was its adoption as a material in DVD pickup lenses (lenses for information readout devices). Manufacturers seeking plasticized glass lenses took particular note of the high level of APEL™'s optical performance.

Encouraged by this response, APEL™ researchers ascertained that the material is also suitable for use in camera lenses, and made successive presentations at academic conferences and in papers noting the possibility of high-quality photographing. The path thus opened up for smartphone camera lens applications for APEL™. APEL™ proved a memorable product for Mitsui Chemicals, as an example of what can blossom out of hardship.

Column: "Molecular structure: the secret to a non-blurry image"

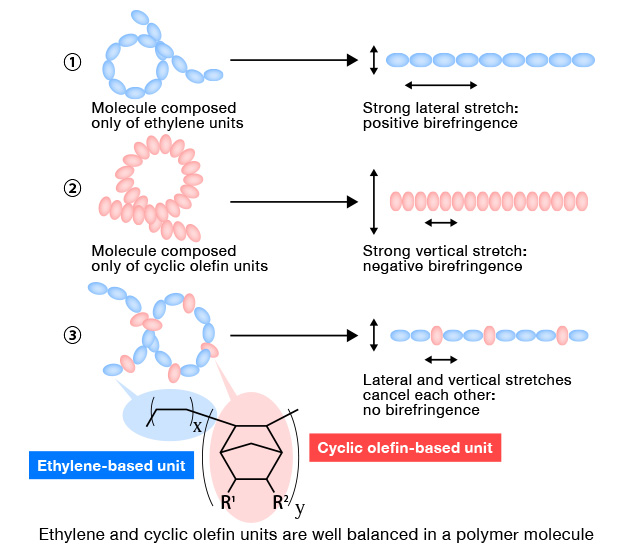

An important aspect of the lenses made with APEL™ is their small birefringence. Birefringence in a lens is an attribute that causes a ray of light to divide into multiple rays due to optical distortion. Use of lenses with small birefringence makes it possible to take clear, non-blurry photographs. Why do lenses made with APEL™ have small birefringence?

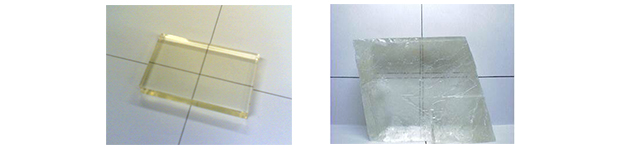

Shown here are an APEL™ photo (left) and a calcite photo (right). Seen through the calcite, the cross-marks written on the back of the photos look doubled. That's the birefringence. By contrast, it is clear that the birefringence in the APEL™ example is very small.

This property is related to the molecular structure of the material. APEL™ is a cyclic olefin copolymer made by the addition polymerization of ethylene and cyclic olefin. The nature of plastics changes depending on the ratio of ethylene to cyclic olefin (x and y values) and the structure of R1, R2 cyclic olefin.

An ethylene unit in a polymer molecule is stretched in a lateral direction when molecule chain orientation occurs during molding, while a cyclic olefin unit is stretched in a vertical direction. (1) In molecules composed only of ethylene units, positive birefringence occurs due to the lateral stretch. In molecules composed of cyclic olefin units, negative birefringence occurs due to the vertical stretch. (2) APEL™ has a well-balanced composition of ethylene and cyclic olefin. This means the lateral and vertical stretches cancel each other out, and that birefringence hardly occurs.